Warehouse management software (WMS) is the central source of information on everything in a manufacturing business. It is your instruction guide for each order and shipment, as well as the auditors. You can see all the data you and your employees collect aggregated into useful reports and automatically detect anomalies or issues that it would otherwise take someone with immense business knowledge to catch. With the four main types of warehouse management systems, your organization will be able to keep inventory more organized, improve safety, and speed up operations, leaving your organization with more time to process orders.

Which Warehouse Management System Is Right For You?

There are many warehouse management systems, but they fall into four system types. Finding the right WMS for you depends on your unique situation. If you’re unsure where to begin, consider reaching out to Orases.

With years of dedication to technology, Orases is ready for any issue you face when implementing a warehouse management system. So if you need a jump-start, reach out to Orases today to see just how simple it can be.

1. Enterprise Resource Planning (ERP)

An Enterprise Resource Planning (ERP) software solution is great for any company looking to improve logistics or shipping issues. Often, small companies that are just beginning to scale will gain a lot of value from implementing a warehouse management system integrated with their ERP system. ERP and WMS systems are both parts of supply chain management but serve different roles.

ERP systems are more designed for an efficient workflow operation. They follow orders or products along a predefined path in the business. Warehouse management systems work harder to give a holistic perspective on the business. They integrate with the warehouse and provide metrics and reports to show you how well you’ve been performing.

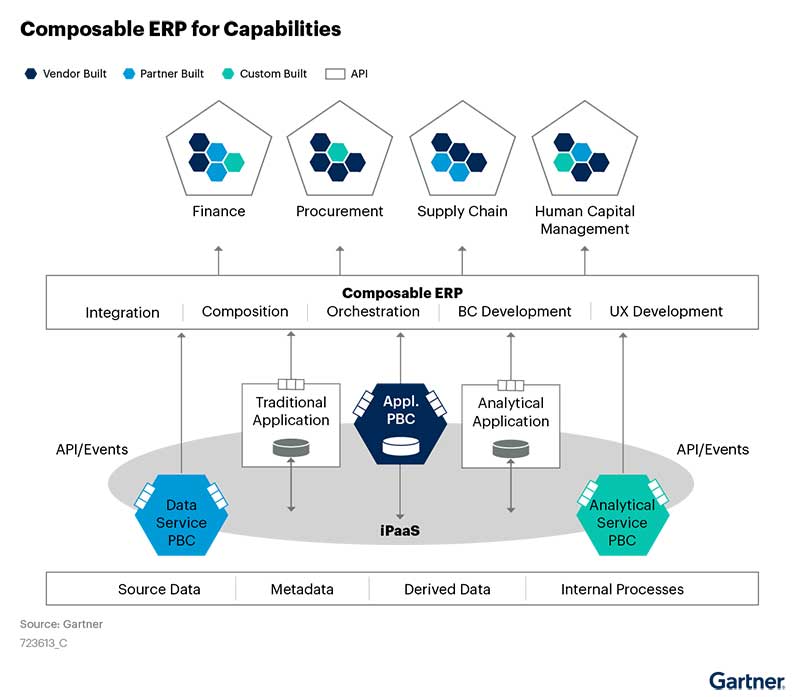

Figure 1.1 shows the various capabilities of custom ERP software and differences between vendor developed (out-of-box software), partner developed (software built internally), and custom developed ERP software solutions (software designed and developed by a custom software development company).

2. Stand-Alone Warehouse Management System

A standalone warehouse management system is the smallest version of a WMS you could consider. They are generally the most affordable solutions, but don’t offer the far-reaching integrations that some other systems offer. This is a great stopgap solution to integrate two systems, like a successful supply chain management system.

Usually, these systems help with inventory and warehouse management, like scanning. Because of this limited utility, businesses typically choose a stand-alone system to integrate with their existing supply chain management (SCM) system, where the SCM will pick up where a more comprehensive WMS would fit.

Because of the slim, simple nature of these systems, they are common choices for warehouses that deal with small batches or flow, have few employees, or have few workstations. They are also easy to set up and easy to use. Depending on your implementation, this could be a good fit for you, but if your business is growing, you might want to consider a different solution.

3. Cloud-Based Warehouse Management System

New technology has revolutionized the warehouse management market. With the option to use cloud-based warehouse management systems, many more businesses can take advantage of the upsides of warehouse management. There are huge advantages to using cloud-based WMS that make them an attractive option for many warehouses.

With all of the tech handled by vetted and trusted companies like Amazon and Microsoft, you can rest assured that your system isn’t just “Always On”; it’s also secure. You don’t have to worry about updates or software patches because that’s all handled on their end. Instead of putting the load on your IT staff, you can trust a cloud solution to help you quickly set up a warehouse management system. Another huge benefit to cloud-based systems is their price. Generally, cloud options are based on usage and are only a small monthly payment.

If your business is ready to grow, you should consider a cloud WMS solution. With easy integration, and tons of support from top-of-the-line vendors, you’ll be in a great position to scale with demand. But, if the buzz words are scaring you away, don’t run just yet.

Orases is more than happy to take the hardship of converting your systems to the cloud. It’s a great solution, but one you might need some outside help with. If you’re wondering whether a cloud WMS is right for you, reach out to Orases. They’ll demystify the cloud and do the heavy lifting for you.

4. Supply Chain Module

A supply chain module is a component that integrates with a warehouse management system to provide shipping, scheduling, vendor management, customer service endpoints, inventory reports, and material handling management.

Most businesses benefit from a full warehouse management system implementation, but sometimes a supply chain module will suffice. It’s a great choice for 3PL providers that already have a warehouse management system but are missing that shipping and scheduling component.

View Our SCM Guide

What Are Key Features Of A Warehouse Management System?

There are many features that make a warehouse management system more useful for certain businesses. Custom code, complex logistics, or minimal implementations are all valid solutions for warehouse management; it just depends on your situation.

Inventory Management

People sometimes call inventory management just part of warehouse management. There is a slight difference; generally, inventory management software can’t exist without some WMS. Inventory management focuses on stock and order fulfillment. Because of the critical nature of this part of a warehouse management system, inventory management is one of the most important features your WMS can accomplish.

Even though some warehouse management systems include an inventory management system, inventory management alone isn’t as helpful or important for business growth. If your business is growing or is mid- to large-sized, an inventory management system will limit your potential. Instead, you’d be better off with a full WMS, an SCM, or an ERP.

3PL

The type of business you do is the driving force for which WMS system you should choose. For example, large companies need robust WMS with full features, but a smaller organization could get by with a simple inventory management system. One choice many decide on is to implement 3PL, third-party logistics.

3PL allows a company to off-load the burden of shipping, distribution, and/or fulfillment. Some large shipping companies with the infrastructure to provide trucks and shipping management offer their services as a way for any company to outsource those expensive parts of every warehouse’s operation. By outsourcing shipping and logistics, any company can scale with their 3PL.

Multiple Clients

Almost every 3PL company needs a warehouse management system for inventory and purchase order processing. For companies with many clients, creating a system that allows you to bill any number of purchasers is important. Most warehouses have to deal with an unmanageable number of clients, but if you’re a warehouse that only deals with one client, this isn’t a solution for you.

As you shop for a WMS, companies offering products will sometimes mention multi-client compatibility. It’s important to determine if the vendor you’re considering supports your multi-client needs. Sometimes a cloud service will say they are multiclient, only meaning that they support several companies. Ensure your vendor offers a multi-client architecture, not just a server shared between clients.

Third-Party Logistics Billing

With your 3PL solution, you can count on your shipments being effective and on time. There are several advantages, but you must be aware that you are off-loading a critical part of your business to another company. You need to ensure there are no mix-ups when it comes to processing invoices and orders.

The best way to do this is through a system in your WMS like a third-party logistics feature. 3PL billing helps to integrate receiving, storage, and shipping with your WMS to couple your system with your shippers.

Value-Added Services

If you have a unique process and feel that your WMS isn’t fully capturing your flow, you might consider implementing a custom solution inside your WMS. A stand-alone implementation will work if, for example, your warehouse is assembling components, not necessarily manufacturing, then you could provide more accurate progress reports for your orders. This might also help with tracking internally and getting shipments ready.

Making your custom code small can make your life a lot easier, but for the lifting required for integrating it into your system, you might want to investigate an outside company. Orases is ready to help you bring your company from 80% to 100%.

Multi-channel Fulfillment Services

If you have multiple warehouses or a global network, you’ll find a lot of benefits from a multichannel fulfillment solution. This solution will be a great asset if you’re shipping between multiple business locations or have many B2B shipments since you need a way to handle order scheduling, bulk orders, order creation, and checkoffs.

Cloud systems are a common solution, as large tech companies can leverage many integrations to help you customize the solution that best fits your needs. This also gives you all the benefits of cloud-based WMS, where they scale with you as your business grows, and you have a quick, cost-effective WMS solution.

Improve Your Warehouse Productivity By Reaching Out To Orases Today

Orases has helped numerous companies meet industry standards with warehouse management systems. If you’re looking for a hand implementing your system, call Orases today. They’ll help you understand everything and leave you confident about your implementation.

Orases has completed cloud implementations, worked with businesses interested in 3PL, and aligned their future WMS implementation to suit their needs. They’re also committed to giving you a result you can count on since there’s nothing worse than a broken tracking system in your warehouse. So make sure you’re getting the job right, and reach out to Orases by calling 301.756.5527 or by scheduling a consultation online today!