Improving Supply Chain Management Processes With Business Management Software Solutions

Deficiencies within the supply chain often leads to a decline in customer retention. Business management software can fix these deficiencies.

Modern supply chains are more complex than ever. Today’s high-demand market has posed numerous challenges for companies, from high shipping costs and shortages of critical components to port congestion and logistics delays. To address these concerns, many businesses are working towards creating a sustainable supply chain to achieve greater automation and cut down on time and resource-intensive processes.

The supply chain is a fundamental part of inventory management and a company’s overall business strategy. An effective supply chain can help companies minimize wait times for in-demand products and improve customer satisfaction. On the contrary, an inefficient supply chain can deplete a company’s resources and have a devastating impact on its reputation.

Improper supply chain management is the most common reason that products go out of stock despite high public demand. Although it is not always possible to predict what products will require a larger supply, companies can prepare for these types of events.

Business management software solutions can be used to continuously optimize and evaluate the supply chain process to generate higher revenue for goods and services rendered.

01

Chapter 01

A Brief Overview Of The 4 Main Supply Chain Elements

The effectiveness of a supply chain has a significant impact on the long-term success of a business. Improving and optimizing a supply chain are some of the best ways to boost profitability and productivity.

From raw material procurement to distribution to customers, every step of the supply chain plays a key role in a company’s manufacturing process. Supply chains are generally made up of four main elements, including integration, operations, purchasing and distribution.

These elements work together to help establish a path to optimal competition that is both competitive and cost-effective. Understanding these four elements of supply chain management can help businesses see where to place focus and what improvements need to be made within the company.

The four main supply chain elements include:

Integration

Integration is considered the “heart” of the supply chain process. This element is an essential part of planning which is necessary for the long-term success of any project. Through integration, the supply chain can receive all the details of interactions and actions.

The main component of integration is data and the way that it is collected, stored and used. By overseeing supply chain integration, companies are better able to coordinate communications with the rest of the supply chain for timely and effective results in the manufacturing process.

Proper collaboration and communication with all parties involved in the supply chain is a vital business strategy that helps save money and eliminate errors.

Companies that effectively integrate each division with one another can build strong teams of experts. When teams are integrated into the sequence of processes, it becomes easier to identify areas for further improvement and to monitor operations as a whole.

Operations

Business operations require a company to have an accurate and real-time representation of their production schedules and product inventory to properly monitor their output and predict production and distribution needs.

The right business management software solution can help companies better align their operations with the remainder of their business. This type of software can also provide companies with reliable and accurate information on current inventories and production to achieve a more effective fulfillment process.

During operations, supply chain managers are tasked with monitoring the processes that are being performed and ensuring that all activities remain on track. Modern manufacturers are often reevaluating their manufacturing strategies to achieve maximum efficiency and performance.

Supply chain operations teams have the potential to make significant improvements to the supply chain, whether they are modifying work patterns during periods of slow production or monitoring equipment and processes to maintain maximum performance.

Purchasing

Another critical element in the supply chain is cost-effective purchasing. Companies are tasked with sourcing products for their supply chain while taking advantage of the most reliable products at the most competitive pricing.

Many companies rely on demand forecasting when sourcing their products to ensure that they have the right type of product at the right time and in a sufficient quantity. One of the best ways that companies can cut down on operating costs is by keeping close track of competing producers, suppliers and demand cycles.

Whether it be supplies, equipment, tools or other essentials to operate the business, companies need a solid understanding of what goods to purchase and how to get them for the best price possible.

Having qualified purchasing personnel, as well as access to reliable business management software, can help companies maintain a strong supply chain. Proper purchasing strategies can also prevent businesses from running short on materials, causing production to face significant delays.

Distribution

The final element in the supply chain occurs when the product is received by customers, either through direct shipping or when purchased from a store shelf. Before products can reach their final destination, companies must develop and implement a well-planned supply chain distribution strategy.

The use of logistics software for employees can help companies properly handle products so that they reach customers as quickly as possible, resulting in greater customer satisfaction and improved brand image.

A company’s delivery and returns processes should be centralized to achieve a real-time view of inventory, stock location and order status, regardless of if the product was ordered online or in-store.

Logistics software can be used to manage the shipment process, whether the business decides to handle this part of operations on its own or source it through a third party. Logistics service providers often deal with services like warehousing, transportation, delivery and similar operations.

02

Chapter 02

Common Supply Chain Management Process Issues

Advancements in technology have helped solve many common supply chain challenges over the last decade. However, many problems continue to burden companies and complicate an already complex supply chain.

Businesses that wish to harness the vast advantages of supply chains must find ways to overcome these difficulties or handle them effectively.

Whether the problem lies with data, cash flow, language barriers or other issues, learning the best way to approach common supply chain management process issues can help companies maximize their profits, deliver goods and supplies in a timely manner, and reduce the frequency of inefficiencies.

It is important to remember that the overall goal of a supply chain is to ensure that companies are able to deliver products on time to customers at the lowest cost possible. Supply chain management (SCM) uses a variety of ideas and methods to develop a production process that has high efficiency and a low amount of waste.

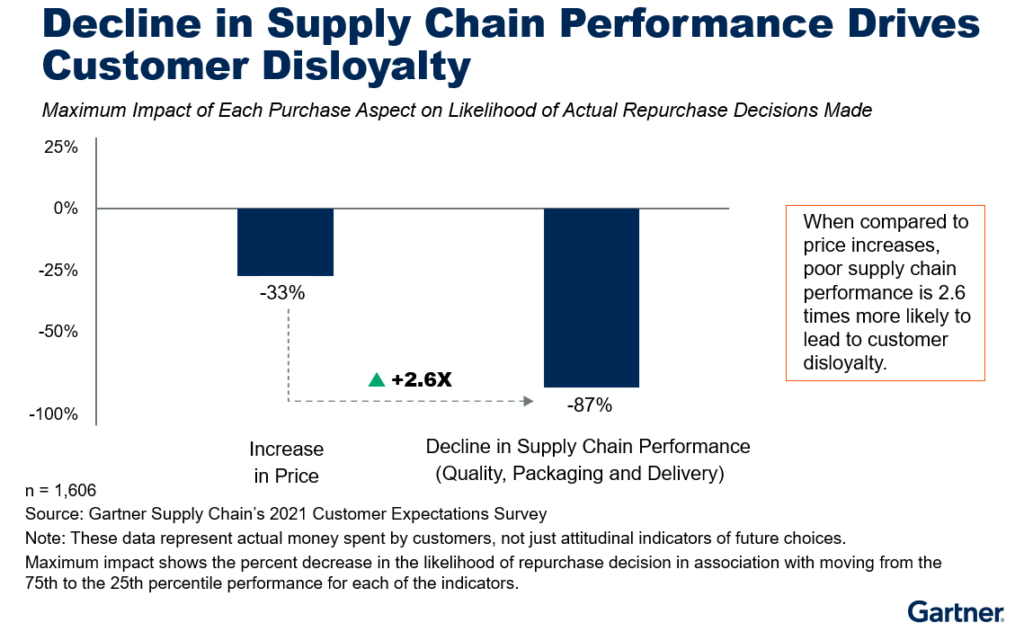

In a recent study reviewing supply chain performance[1], Gartner reported that supply chain issues are three times more likely to result in consumer disloyalty than an overall increase in price. The chart in Figure 2.1 shows the decline in supply chain performance revolves around quality control, packaging and delivery of the product.

Here is a look at some of the most common supply chain management process issues that a company may encounter:

Lack Of Quality Control

Supply chain management has a direct impact on product quality. Proper quality control in the supply chain can give companies a competitive edge in the marketplace and reduce overall operating costs. However, a lack of quality control can result in prevalent waste beyond a tolerable amount. It is important for companies to actively review the components of quality management systems to avoid and properly address supply chain issues.

There are several issues that can arise in the supply chain due to a lack of quality control. When supply chain quality control is poor, products are more likely to break or experience premature wear before the warranty expires. Customers who are forced to return a product due to poor quality control often lose their preference for the company and opt for competitor products in the future. This can ultimately have a negative impact on the company’s brand and reputation.

Inventory & Order Management

The primary goal of any retail-related business is to get their product to their customers on time. Keeping track of inventory and managing it effectively can help companies meet their demand and generate sales. There are several challenges that businesses may encounter when managing inventory and orders, such as inconsistent tracking, warehouse inefficiencies, inaccurate data, changes in demand, limited visibility, problem stock, and other supply chain complexities due to daily supply shifts.

Companies must take the necessary steps to overcome inventory and order management issues to prevent repercussions. The use of business management software can be advantageous for companies as many offer key features like centralized tracking for accurate and automatic inventory updates. These software solutions can also measure and report warehouse performance metrics like customer satisfaction and inventory turnover, as well as offer demand forecasting tools and stock auditing features.

Cross-Department Information & Data Sharing

Maintaining access to supply chain data is essential in a modern-day supply chain. Access to data can help companies better manage their supply chain and make informed decisions on how to reduce risks and make improvements.

Consider implementing some common metrics to help improve supply chain efficiency, such as:

Cycle Time

Develop a streamlined cycle, such as request-to-approval, approval-to-purchase and invoice-to-payment.

On-Time Delivery Reporting

Understand what orders are outstanding from both a supply delivery management perspective and a financial perspective.

Consolidation of Items and Vendors

This is an area commonly used to identify cost savings and decrease suppliers that need to be managed.

Budgetary Controls

Ensure that spending occurs within the budgeted amount.

It is important for companies that wish to improve their supply management to have the tools necessary to capture these metrics to improve reporting and better manage company spending.

Scaling The Fulfillment Process

Managing day-to-day growth, in combination with seasonal peaks, can be an ongoing challenge for companies. Supply chain constraints and an unprecedented rise of direct-to-consumer (D2C) eCommerce triggered by the COVID-19 pandemic have directly affected companies’ ability to scale order fulfillment.

Scaling the fulfillment process involves a number of considerations, such as how best to eliminate bottlenecks caused by issues with data or an overall lack of visibility into labor, equipment, processes or technology. When these issues are not quickly resolved, they can add to costs and create inefficiencies in the supply chain.

When it comes to scaling the fulfillment process, warehouse automation is also a must. Warehouse automation helps boost speed, support scalability and ensure order accuracy. In turn, this helps to improve customer satisfaction. The use of order management systems (OMS) and warehouse management systems (WMS) are essential for proper fulfillment.

Transportation Planning & Execution

Transportation has one of the biggest impacts on a business of all of the supply chain processes. Having the right transportation planning and execution measures in place can help ensure that deliveries to and from the facility flow as smoothly as deliveries to customers. Due to the importance of transportation, warehouse managers should closely examine the state of their transportation within the supply chain.

Staying up-to-date with technological advances is key to remaining competitive. There has been an explosion of vehicle technologies used in recent years, such as internet-connected sensors and automation features, allowing professionals in the industry to perform their jobs more effectively. However, these technologies also pose certain risks, such as cyberattacks by hackers. The use of up-to-date and comprehensive security software is essential to remain safe.

03

Chapter 03

Top Business Management Software Solutions To Consider

The right business management software solutions make it simple to manage a business more effectively. However, with so much competition in the software market, it can be difficult to determine what solution is best for a particular business.

There are big-name products on the market created by big-name vendors. There are also smaller and more affordable packages that can be just as efficient for small businesses. When comparing these software solutions, take note of every aspect, such as cost, features, ease of use, tools and other essential components.

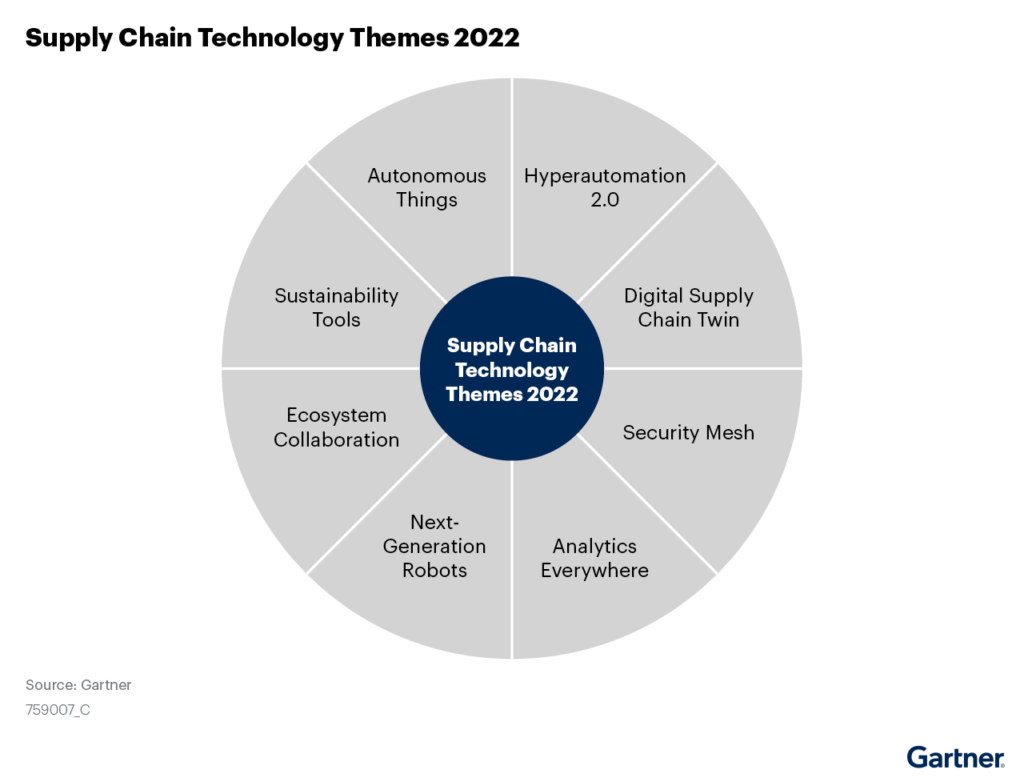

According to a 2022 strategic supply chain technology themes study[2] performed by Gartner, supply chain leaders reported 8 primary technology trends they use as agile solutions to their organizations business goals and objectives.

Figure 3.1 shows these technology trends including: autonomous technologies, hyperautomation 2.0, digital supply chain twin, security mesh, advanced analytics, robotics, collaborative ecosystems and sustainability tools.

When it comes to supply chain management, there are several key types of business management software solutions that companies should consider. These include:

Option #1

Enterprise Resource Planning Software

Enterprise resource planning (ERP) is a common process used by businesses to manage important areas of their organization. ERP software applications can help companies implement resource planning by integrating the processes required to run their businesses with one convenient system.

With ERP applications, people from different departments can effectively communicate and share information more easily. These applications can also collect data about activities that occur within certain divisions, allowing team members to remain as productive as possible. ERP software can also make companies more self-aware by combining information about finance, production, human resources and distribution into one system.

Who Should Consider Acquiring Custom ERP Software?

Many companies wonder if they should invest in custom ERP software. Custom ERP software focuses on building a scalable business-tailored system that facilitates data-driven decision-making and integrates important business management functions. Custom ERP software is based on the unique needs and experience of a company and can be used to solve common issues not possible with off-the-shelf software.

Nearly any organization that seeks to improve its operations through integrated communication functionality and process automation can benefit from acquiring custom ERP software. Businesses in the manufacturing industry in particular have a lot to gain by purchasing and implementing this type of solution. Custom ERP software can help manufacturers automate and digitize their business operations, allowing them to run more efficiently while saving time and money.

Custom ERP software also has the potential to increase the speed and overall accuracy of production, which is critical in the manufacturing field. For the majority of companies that buy and integrate enterprise resource planning solutions, the importance of ERP heavily outweighs the initial cost.

Benefits Of Implementing Enterprise Resource Planning Software

The benefits of implementing enterprise resource planning software center around what it can do for a business. ERP solutions can help manage a wide range of functions through automating and streamlining day-to-day business operations.

One of the biggest benefits of using this type of software solution is the competitive advantage that it can provide to companies. While the cost of investing in custom ERP software can be intimidating, the cost of not investing can be even greater. Implementing ERP solutions can help businesses stay ahead of the competition as there is a significantly reduced risk of errors.

There are also many other advantages of implementing enterprise resource planning software. Some of these benefits include:

Access To Real-Time Data & Information

With custom ERP software, companies are able to view data and other information in real-time, such as inventory status, employee time tracking and distribution routes. Without real-time data, businesses are unable to update customers on their order status. If a competitor has this technology, customers may choose to go to them in the future if they can provide better information and service.

Having access to real-time data can provide companies with many incredible insights, such as more accurate scheduling, significantly better service, cost savings, and enhanced sales and marketing data. Real-time data and information also allow businesses to spot errors immediately instead of later on in the supply chain. This can prevent too many products being rejected due to quality issues. The same issues can occur in the warehouse when too many products arrive damaged. ERP software can help prevent these types of issues from occurring.

Streamline Supply Chain Communication & Processes

Communication is an essential component of any thriving business. Unfortunately, many companies find that their teams work in solos because proper communication and collaboration in the workplace require more effort and time. With ERP software, communication and processes are easily streamlined by providing employees with access to the data they need to do their jobs efficiently.

With better communication and real-time updates across the company, businesses can start to see the bigger picture and reach their goals faster. Employees gain the tools necessary to make proactive decisions while also feeling like a valuable part of the team. The overall effect that custom ERP software can have on a business includes increased efficiency, a reduction in operational costs and higher employee engagement.

Enhanced Security Protocols

Security is a major concern when it comes to any software but especially software like ERP which is heavily relied upon by businesses on a daily basis. Fortunately, good ERP systems make it easy for companies to restrict the access of employees and managers to only processes that are relevant to their unique job roles.

Through role-based security, employees are only given access to the tools and functions that they actually need to complete their duties. Permissions for all other functions and tools are locked down so that employees can not access any functions behind their roles. ERP also implements other security measures to ensure that information is kept safe, such as the use of secure and encrypted passwords.

Scalability For The Future

When companies experience an unexpected influx of new customers, they typically want to know the cause. Maybe the business appeared on a popular website or on the news. Or perhaps the company’s new product has experienced sudden popularity. Regardless of the reason, it is critical to have ERP software to meet changes in demand quickly and efficiently.

An ERP program should be capable of processing a large amount of new information as it is received by the company. This means that the software must be able to add as many new users and devices as necessary to keep up with demand. When an ERP cannot handle a sudden flood of data, it can result in lost customers and wasted time. Buying and implementing custom ERP software is one of the best things companies can do to achieve scalability in the future.

How To Choose The Right Custom ERP Software For Your Organization

By choosing the right custom ERP software, organizations are able to vastly improve workflow efficiencies through automations & integrations.

Option #2

Supply Chain Management Software

Supply chain management software, also known as SCM software, is an innovative tool used by companies to manage various activities across the supply chain. This popular software solution is often used across supply chain operations for quality management, vendor management, distribution and logistics.

Many businesses find SCM software to give them greater control and better visibility over their increasingly complex supply chain. As a result, businesses can enjoy greater productivity and feel better prepared to deal with disruptions. SCM is such a complex and expansive undertaking that manufacturers, suppliers and other associated parties must communicate and collaborate to manage risks, create efficiencies and quickly adapt to change.

Who Should Consider Custom SCM Software?

Supply chains are growing more sophisticated each and every day, forcing businesses to seek a solution for managing them. To make matters worse, management and manual tracking have become less efficient and are highly susceptible to errors. Fortunately, companies can overcome many of these risks by investing in supply chain management software. Nearly every business that manages a supply chain can benefit from custom SCM software, especially businesses in the manufacturing industry.

From monitoring and customer service to warehouse and supply management, custom SCM software has become a must-have for any modern business that seeks to gain an edge over its competitors. With access to the right software solutions, companies can achieve a wide range of benefits, such as the significant improvement of the flow of products and finances, in addition to enhanced communication and collaboration.

Benefits Of Implementing Supply Chain Management Software

Supply chain management focuses on managing the many moving components of a supply chain while aiming to achieve optimal customer satisfaction, competitive advantages and cost savings. In the past, separation sections of the supply chain resulted in self-contained problems that were individually handled by those who directly interacted and managed them. Today, supply chains are viewed as interconnected series of components that work together to create and deliver products to customers as quickly as possible and with maximum accuracy.

Supply chain management software can do a lot for businesses in all industries. These innovative tools have the power to automate physical supply chain processes and deliver valuable analytics and business intelligence that companies can use to achieve faster growth. In addition, supply chain management software can help teams enhance their business operations to ensure that they are as effective and efficient as possible.

Some of the key benefits of implementing supply chain management software include:

Improved Execution Time Throughout The Supply Chain

One of the top advantages of implementing supply chain management software is improved execution time throughout the entire supply chain. SCM solutions can help organizations improve the coordination, efficiency and completion times of deliverables throughout each section of the chain, such as material purchasing, storage and processing within the warehouse, manufacturing of products, billing during the fulfillment process and the transportation of goods to customers.

Maintaining a great execution time can have a major impact on a business’s long-term success. Improved execution times throughout the supply chain can keep production running smoothly and ensure that customers are happy. SCM software can also help ensure that shipments are free of errors.

Automation Of Major Processes

Automation across supply chains has made it possible for supply chain operations within businesses to perform tasks with little to no human interaction or intervention. These automation methods can vary significantly in functionality, size, cost, intelligence and dexterity, but offer benefits to supply chains regardless.

Through automation, businesses can drive value through direct and indirect operating cost reduction and by increasing revenue potential. There are other major benefits that businesses can enjoy when they choose to automate their major processes, such as decreased operating costs, increased volume, increased productivity, improved accuracy, improved compliance, improved time savings and smooth integration with large suppliers. Automating tasks is an overall efficient and convenient way to manage a supply chain.

Reduction Of Excess Materials & Resources

Waste of valuable materials and resources is always a concern in manufacturing and other industries. Many companies strive to achieve higher efficiency to reduce the waste of excess materials and resources. Having real-time data available from supply chain management software can tell businesses about the availability of raw materials and possible manufacturing delays, allowing companies time to implement backup plans that prevent waste.

Less waste also means a noticeable reduction in costs. Lowering costs in the supply chain can have a significant impact on a business’s bottom line and overall success. Supply chain management tools enable companies to minimize costs and reduce their overheads through improvements in quality control. Greater control over this area of the supply chain can also help businesses meet strict compliance procedures.

Increased Collaboration Between Partners, Suppliers & Distributors

Good communication and collaboration are essential in supply chain management. Partners, supplies and distributors must all be on the same page for operations to run smoothly across all sections of the supply chain. Supply chain management software provides companies with a unified system that integrates all sections of the supply chain and gives businesses greater visibility across the entire chain.

With help from custom supply chain management software, all supply chain sections can be easily updated as needed. Companies can quickly view data through the supply chain for accuracy and clarity, as well as reduce the frequency of errors or duplication of work. Collaboration between partners, suppliers and distributors that go beyond the normal course of day-to-day business can lead to significant improvements in the long term.

Option #3

Warehouse Management Systems

A warehouse management system (WMS) is a type of software application that helps manage the operations of a distribution center (DC) or warehouse. WMS applications offer businesses a range of capabilities, such as put-away, receiving, stock location, cycle counting, inventory management, wave planning, task interleaving, order picking, order allocation, packing, shipping and various other functions.

The warehouse management systems market breaks down into several types of vendors, including supply chain management (SCM) suite vendors, application mega-suite vendors, specialist WMS suite vendors, material handling equipment vendors and independent WMS component vendors. WMS offerings can differ in several areas, such as adaptability, usability, scalability, decision support and life cycle costs. Companies should aim to focus on the depth of their WMS offerings for the most sophisticated operations.

Who Should Consider Custom Warehouse Management Systems?

It is important for companies to define their requirements and accurately calculate their return on investment (ROI) when investing in custom warehouse management systems. Different WMSs have unique features and tools, such as logistic management, customer service and inventory tracking, that must be considered.

Nearly any business that deals with warehouse management can benefit from having a custom warehouse management system in place. Even small and medium-sized businesses in search of expansion often find WMSs advantageous as they can greatly aid in processes like billing and product shipment.

This type of innovative system allows for maximum visibility of inventory, customer service, storage capabilities and sales. With the appropriate WMS in place, businesses can also analyze changes in their current processes, check the volume of orders and examine shipments with ease.

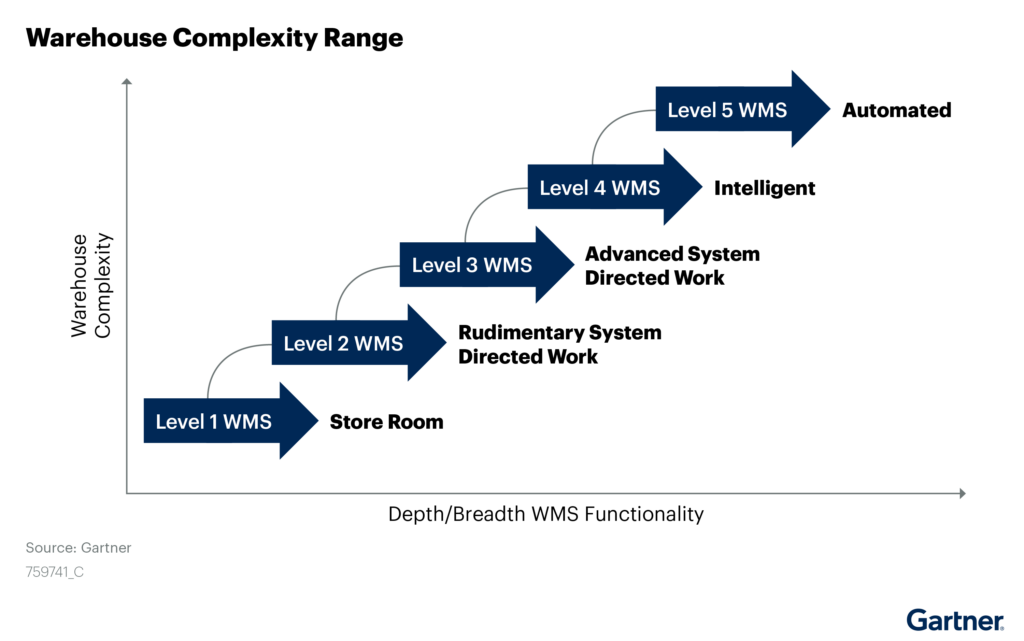

Gartner describes how varying levels of warehouse complexity match up with the overall functionality required from a warehouse management system, as seen in Figure 3.2. Categorizing the overall complexity of a warehouse is a great exercise for organizations to perform in order to provide a clear understanding of the functionality needed from their custom WMS.

Benefits Of Implementing Warehouse Management Systems

With warehouse management systems, businesses can gain visibility into their entire inventory and better manage their supply chain fulfillment operations from the warehouse to the store shelf. With digital technology and the internet continually transforming how customers make purchases, companies are often facing disrupted supply markets and changes in customer buying patterns which adds complexity to the supply chain.

Warehouse management systems allow businesses to meet their customers with an enhanced fulfillment solution that offers scalability, market reactivity and real-time visibility. Here is a look at some of the top benefits of implementing warehouse management systems and why custom software is the ideal solution.

Ramping Up The Fulfillment Process

Companies that wish to remain competitive in a new fulfillment economy must learn how to quickly adapt. By moving to a warehouse management system, businesses can essentially ramp up their supply chain system faster. In addition, powerful logistics capabilities become available to businesses within a matter of weeks instead of waiting months. WMSs can also be successfully integrated with other systems to support multi-channel fulfillment processes.

Warehouse management systems can deliver the same level of functionality as most on-premise systems but without the massive IT overhead. A move to the cloud can also help eliminate the need for software, hardware and IT specialists needed to update and maintain the system. Instead, businesses can get up and running quickly and at an affordable cost.

Integration With Existing ERP & SCM Software Solutions

Custom warehouse management systems are capable of seamlessly integrating with existing ERP and SCM software. These solutions also have the functionality and flexibility needed to integrate with future software and systems.

Ongoing improvement of processes is a major benefit of WMS solutions. As a valuable technological tool, these systems enable continuous improvements that help businesses keep up with current changes. WMSs can also be implemented in phases to allow for regular updates with newly developed features and to keep warehouses as efficient as possible.

Identification Of Staffing Capabilities & Scheduling

A company’s employees are the backbone of a business and can make a significant impact on supply chain management. Custom warehouse management systems can provide organizations with the ability to identify their staff’s greatest strengths and weaknesses. Once this information is known, leaders can distribute work based on these factors to ensure the most optimal job roles possible.

Schedule availability is also an important component of WCM and has the potential to improve the rate of production and ensure that a full staff is always scheduled. Scanning may be used during employees’ entry into the warehouse, as well as throughout their various movements, to help eliminate the need to double-check work, resulting in saved time and greater productivity.

Visibility Of Current Product Volume

Another major benefit of custom warehouse management system software is the visibility of current product volume. With the right software, companies can gain a full view of their current volume of products being stored within the warehouse. This information can prove useful as it provides users with the ability to accurately report product volume and the amount of space still available.

By combining WMS automation with scanning and other location tracking methods, companies can achieve enhanced visibility and reduce unwanted situations like lost, forgotten or misplaced inventory in the warehouse.

Option #4

Inventory Management Software

Inventory management software is commonly used for developing a process of managing and tracking inventory. This is especially important to have as an organization scales and the supply chain becomes more complex. Inventory management software provides companies with visibility into their entire stock, helping them to maintain an optimal amount of stock to keep orders flowing out the door without storing too much in excess.

This type of software can also be used to automate critical tasks and decrease the risk of human error. Features needed in inventory management software are dependent on the industry and the unique operations performed by the business.

Who Should Consider Custom Inventory Management Software

Any business that needs assistance managing its inventory can benefit from investing in custom inventory management software. Business leaders who want to improve the way that they maintain, track and order new stock often find custom inventory management software to save them considerable time and money.

These solutions can also be useful for automating important tasks and enhancing a business’s accounting capabilities. Inventory management is critical for any business that maintains raw materials or goods and keeps them on-site. With this software in place, companies can effectively streamline processes, reduce common errors, and optimize the way that they order and maintain the products they sell.

Benefits Of Implementing Inventory Management Software

The benefits of implementing inventory management software are numerous. By investing in a custom software solution, companies in nearly all industries can streamline the process of inventory control and better track the journey of incoming and outgoing goods. This is especially important for businesses in certain industries that deal with the inflow and outflow of goods, such as retailers, warehousers and manufacturers.

A great inventory management software, with support from comprehensive inventory management processes, can provide businesses with a complete view of their entire inventory even if the goods are spread across multiple locations. There are also other benefits of implementing inventory management software, such as the following key advantages:

Reduced Risk Of Inventory Overstock

One of the most common problems that companies can run into within the supply chain is inventory overstock. Inventory overstock occurs when a business orders or makes too much of a certain product. The result is often wasted storage space, products that sit too long on the floor and wasted money on products that take too long to sell.

Inventory management software solutions are designed to prevent this type of problem from occurring. With a solid inventory management strategy, businesses always know what is in stock and therefore only order the amount of inventory that they actually need to operate effectively.

Advanced Data & In-Depth Analytics

Inventory management software provides companies with in-depth analytics that help them better understand what products sell the best and which sell the lease. This type of data can be highly valuable as it allows for accurate forecasting and ordering. Greater insight can be useful for maintaining stock control. It also allows business leaders to more easily spot sales trends or even track products that have been recalled or have upcoming expiration dates.

Advanced data and in-depth analytics from inventory management systems can also lead to greater productivity. When businesses have good inventory management solutions in place, they can save a significant amount of time that could be better spent on core activities designed to help scale the organization.

Improved Relationships Between Vendors & Suppliers

Businesses also aim to create long-term relationships with the vendors and supplies they enjoy working with the most. There are many ways that companies can maintain these good relationships while also saving money. Inventory management software helps companies gain a better understanding of what products sell the most. With this information, business leaders can better negotiate with vendors and suppliers to get the best prices on bulk goods.

Inventory management solutions can provide a wide range of valuable insights designed to help companies grow and maintain good terms with vendors and supplies. When on good terms, businesses can actually save money without sacrificing product quality.

Quicker Inventory Turnover

Quick turnover is always sought after by businesses that sell any type of product. The more products sold, the more money the business generates and that is good for everyone involved. Inventory management software can help companies achieve quicker inventory turnover by providing information on what products sell the quickest. With this information, business leaders know to stock up on certain items to achieve quicker turnover and higher overall profits.

A solid understanding of both demand and availability is key to higher inventory turnover. Consider investing in custom inventory management software to keep close track of demand in the industry.

Option #5

Transportation Management Systems

A transportation management system (TMS) refers to a logistics platform that uses technology to assist businesses with the planning, execution and optimization of the physical movement of goods. Whether goods are incoming or outgoing, a TMS can help ensure that the shipment is compliant and that all necessary documentation has been provided.

TMS provides companies with greater visibility into the daily transportation operations and ensures the timely delivery of goods and freight. This type of software can also help streamline the shipping process, making it easier for companies to manage and optimize their transportation operations, whether it is by sea, air or land.

Who Should Consider Custom Transportation Management Systems?

Transportation management systems play a vital role in the supply chain and affect every part of the process. These types of systems are primarily used by companies that need to move, ship or receive goods on a regular basis, such as retail businesses, manufacturers, eCommerce companies, distributors or companies that provide logistics services, such as logistics service providers (LSPs) or third-party (3PL) and fourth-party (4PL) companies.

Businesses in almost every industry, from life sciences to construction, rely on transportation management systems. TMS solutions have made it easier and more affordable for businesses of all sizes to take advantage of the benefits that these systems provide.

Benefits Of Implementing Transportation Management Systems

When businesses need to move freight reliability, efficiently and affordably, they rely on transportation management systems. TMS offers solutions for transporting freight against a range of modalities, in addition to intermodal moves. These systems can also be used to handle a wide range of freights, from tiny packages to large shipments.

There are many benefits to using TMS solutions rather than traditional transportation management models, such as better customer service and improved warehouse productivity. Here is a look at some of the other benefits of implementing transportation management systems within a business.

Real-Time Delivery Tracking Capabilities

Tracking deliveries can become much more complex over time as a business grows and accepts more customers. Without help from a custom transportation management system, businesses may have difficulty providing customers with the most up-to-date tracking information, resulting in reduced customer service.

With a transportation management system, businesses can keep close track of where shipments are at all times. Businesses are also notified when cargo is late or has not arrived at the destination as scheduled. Companies also benefit from knowing when service outages have occurred so that they can make any necessary adjustments as soon as possible. Businesses can even create more effective delivery route schedules by calculating the time it takes to complete a route using tracking data.

Improved Order Fulfillment Accuracy

The main goal of any business that provides a product to a customer is to accurately fulfill the order and get it to the customer as quickly as possible. The use of a quality transportation management system can help streamline this process. TMSs help improve the accuracy of shipping significantly, ensuring that customers receive their packages fast and without errors.

Shipping mistakes and other anomalies are often eliminated with the use of transportation management solutions. Customers are not adversely affected by these problems that could arise during transit, resulting in greater customer service and enhanced brand reputation.

Elimination Of Manual Documentation & Administrative Tasks

Another major benefit that companies can enjoy when they purchase and implement a transportation management system is the elimination of manual documentation and other time-consuming administrative tasks.

Using a transportation management solution can save businesses both time and money as this software helps automate all accounts. TMSs can also reduce the amount of paperwork and other documentation required to keep the business running smoothly which can be a win-win situation for everyone involved. Administrative expenses often fall while improper billing is minimized. Invoicing mistakes and other errors can also be greatly reduced with TMS solutions.

Increased Efficiency Of Dock Scheduling

Supply chain and logistics businesses across the globe often experience a similar problem. Improper scheduling and lack of constant monitoring can cause orders to fall behind and shipping docks to become congested. One of the best solutions for this common problem is to set up transportation management software to properly manage dock schedules.

The right software solution can make dock scheduling more efficient by providing the data needed to carefully plan and execute shipping dock arrivals and departures. TMS solutions can help cut down on waiting times and help ensure that high-quality transportation is available from one point to another by aligning deliveries with dock schedules.

04

Chapter 04

How To Choose The Right BMS Solution For Your Organization

Choosing a business management system for an organization is no easy feat, no matter how many years the company has been in business or how confident they are in its needs.

There are many things to consider when choosing a BMS solution, such as price. A modern BMS system should also help companies gain a clear picture of their projects’ status and progress, as well as customized workflows for different scenarios.

Vendor management is also an important consideration when choosing a BMS solution. The software should have the capability to filter and select vendors based on various criteria. It should also provide an online tracker of resource availability, as well as a vendor portal where vendors can update their profiles. Other aspects to consider include integrations, reporting, finances and support.

Does Your Organization Handle All Aspects Of The Supply Chain?

Businesses that handle every aspect of the supply chain should consider investing in either a custom ERP solution or a custom supply chain management solution. Supply chains have several elements that need to be managed, including planning, sourcing of raw materials, manufacturing of goods, delivery and potential returns. Each step is important and requires dedication and hard work to ensure that operations continue seamlessly.

Reach Out To Orases To Get Started On Your Business Management Software Solution Project Today

Orases is a custom software development company that focuses on building custom solutions for businesses to help them reach their vision. At Orases, customers will find a wide range of services available, including custom software development. From ERP software and CRM software to cloud applications and system integration, businesses can trust Orases to provide support every step of the way.

When it comes to supply chain management, Orases is here to help. The knowledgeable team at Orases can assist in the development of both custom ERP software or custom supply chain management software. With custom software, customers can rest assured that the solution is geared directly to their industry and specific business requirements. For more information about supply chain management or to speak with Orases about custom software development, schedule a consultation online or call 301.756.5527.