A custom warehouse management system (WMS) can be designed and developed to increase the efficiency of various supply chain processes, ranging from inventory management to transportation logistics. See how your organization is able to improve workflows and simplify processes through the advanced features of a warehouse management system.

Taking Inventory Processes To The Next Level With A WMS

Inventory is tracked and organized in all elements of the warehouse. With a warehouse management system, storing, picking, staging, loading, and everything in between is logged in the software. The software also creates a checkpoint at every step, taking a snapshot of the inventory that should be present.

Everything logged is associated with a bill of materials, or a software tally that your company can use to validate inventory, WIP, or shipments. This sort of tool integrates the warehouse with the business.

Warehouse management systems enable a lot of speedup operationally. Robotic slotting or picking systems integrate with WMS to automatically transport inventory into storage or to the proper workstation. The work orders for a given shipment are automatically generated, printed, and ready for the truck. These pieces of software are designed for the everyday user in mind.

Warehouse management systems enable a lot of speedup operationally. Robotic slotting or picking systems integrate with WMS to automatically transport inventory into storage or to the proper workstation. The work orders for a given shipment are automatically generated, printed, and ready for the truck. These pieces of software are designed for the everyday user in mind.

For example, warehouse operators integrate with terminals to confirm certain aspects of the workflow. But often, the work orders are entered from an office, so there’s usually a portal or admin website that allows for configuration and customization of the warehouse management software.

Overall, WMS’ create a healthy mindset in the warehouse. They provide a real-time view of the whole supply chain. A smart management team integrates this real-time data into operations, empowering the operators and overseers to adjust if there’s a slowdown or a surge in WIP.

In real-time, you can make adjustments to production to balance production speed with supply. You can also program notifications to alert concerned parties about low supply. You can even create a rule to automatically buy more inventory at a certain threshold or alter the frequency of ordering and delivering certain inventory.

Utilizing A Warehouse Management System In A Fluctuating Workplace Environment

The advanced features of a warehouse management system enable any business the ability to be safe during a pandemic, and allows them to conform to social distancing. It also enables employees to keep an appropriate distance at work, which would be a major concern before implementation.

With careful planning, warehouse management software can use logic to determine if two employees are scheduled to be in the same area. With this in mind, the software can create a schedule for employees to follow that ensures everyone is at a safe distance on the floor or in the warehouse. To do this, the warehouse management software has to manage inventory so that every station is kept busy.

Improving Operations & Processes With A Custom WMS

Therefore, it’s in the best interest of the warehouse and employees to offload some of the simpler or automatic tasks that a WMS can do.

Database Integrations & Process Automations

Another huge benefit that everyone in your operation will be happy about is the implementation of scanners in the warehouse. For example, suppose you use scanners with your WMS at receiving when you get your raw inventory. You now automatically have the first entry for that material in your system, and the tracking has already begun.

Now, at every step of the process, operators should scan the same barcode to associate the run on the machine with the present orders. This creates a tight audit for anyone tracking down an order or missing parts. By having a database which integrates into various warehouse processes and departments, decision-makers are able to easily view the status of operations across the organization in real-time.

A warehouse management system doesn’t just simplify auditing and inventory management, but also has the ability to improve processes via automations. Custom WMS’ are able to interact with machinery to automatically configure the machine for the work it’s about to do based on the scanned order.

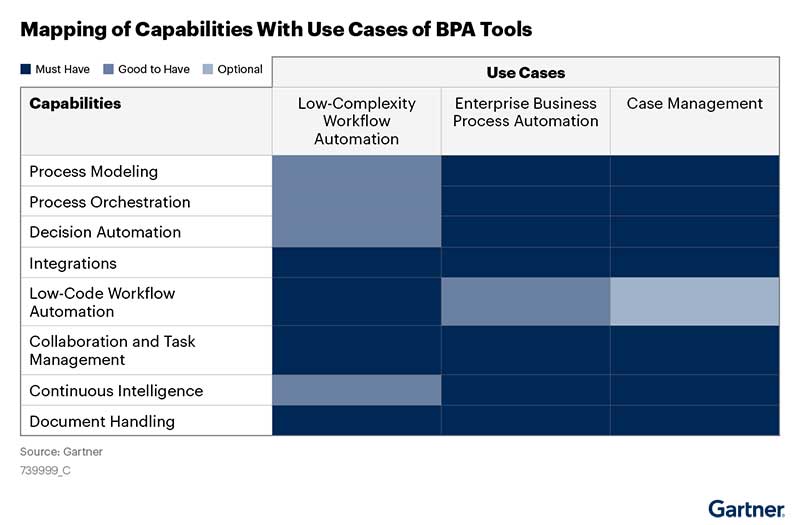

Figure 3.1 shows an example of a graph that can be used by organizations to map out their capabilities and rate them based on priority of what business process automation tools, like custom warehouse management systems, can offer.

Reduction Of Costs & Improved Inventory Control

One of the first selling points of a WMS is its ability to reduce costs in the long run. Using a WMS, managers can quickly decide each day what the best orders to run are, based on inventory levels, worker availability, WIP, and more. All of the data you need to optimize your efficiency are right there inside the warehouse management solution.

Another improvement that warehouses can aspire to achieve is a steady flow of product out and inventory in. If you can make your internal process more consistent, you can reduce the amount of stocked inventory and save money on storage.

If the new inventory each day can go right into the production flow, and the finished product can go straight to shipment, there will be a lot less maneuvering of work orders, storage of inventory or WIP, and this will greatly improve overall efficiency and reduce costs. You will also be freed up to buy more inventory to support your production, even if there isn’t space to store all the inventory in the warehouse at a given time.

The best way to make sure this system works and avoid a catastrophic traffic jam is to implement a rule to follow, like FIFO (first in, first out) or FEFO (first expired, first out). With this guiding rule, you won’t need a manager’s help to know what to work on and what should be shipped.

With a better idea of how much inventory you can process in a day, you’ll be able to tune your deliveries to perfectly match the flow of operations, creating big savings and bigger profits.

Advanced Data Analytics & Visualizations

There is no better way to improve an organizations’ decision-making capabilities and prepare for the future than having access to historical data and statistical measurements. By implementing a custom warehouse management system, organizations are able to retrieve precise data points and create visualizations that can be easily interpreted and used to make critical enterprise-wide decisions.

Utilizing advanced visualizations and reports to convey the logic and reasoning behind certain organizational changes or decisions can lead to a higher percentage of buy-in and overall engagement from employees and stakeholders alike.

Pin-Point Tracking Capabilities

Once you have your workflow defined, and everyone is on the same page about how it functions, you’re in a position to take full advantage of the power of a WMS. For example, if there was a high-priority order or a shipment that was going to be run late, managers should have the power to push that order ahead in the queue to ensure it was shipped on time.

Tracking has become a huge part of the WMS. Whether it’s because of clients wanting more clarity into shipping, clarity into WIP, or if its internal tracking of orders, you should be able to see what’s running, what will run, and what has run, all at a glance.

A huge use case for highly integrated WMS tracking is in the event of a quality issue. If there’s a recall on a product, it’s required that you be able to find all the contaminated inventory and assess if any of the product needs to be recalled as well. Because of the scanners, the data is all there in the system. It’s as simple as querying to find infected orders or inventory and addressing the problem.

Begin Planning Your Custom Warehouse Management System With Orases

Any single part of this transformation can be a huge burden on a warehouse. Manufacturing simply isn’t designed to change overnight; that’s part of why it’s so stable. If your organization is ready to start automating processes and improving supply chain management processes, reach out to the experienced custom software developers at Orases by calling 301.756.5527 or by scheduling a consultation online.